- News & Events

- Blog

- Follow us

Application fields: mine, metallurgy, building material, highway, railway, water conservancy and chemical industry

“40 years of senior mining machinery solutions”

Made in China

Two weeks delivery, custom cycle, please consult

Hammer crusher is applicable for various hard and fragile materials, such as limestone, coal, salt, gypsum, alum, brick and tile, etc. The compressive strength of materials should not be in excess of 150 Mpa. Hammer crusher is mainly used in industries such as cement, coal separation, electricity generation, building materials and compound fertilizer, etc. Hammer crusher can crush materials with different sizes into equal particle, which favors the next procedure.

In the hammer crusher, the motor drives the rotor to rotate at a high speed through the belt, and on the rotor there are series of hammers. When the materials get into the working area of hammers, the rotating hammers with high rotation speed are crushing them; the crushed products meeting the required size can be discharged by the outlet and become the final products; the large size products are brought back to the crushing area by the hammers for being re-crushed until they reach the required size

1. High crushing ratio.

2. The granularity can be adjusted according to the requirement of customers.

3. Reduce the cost by 40%, energy consumption, and investment.

4. Simple structure and lightweight, easy operation and maintenance.

5. Single molding without secondary crushing.

The hammer crusher is a common selected equipment for small-scale sand and gravel crushing. The investment cost of the equipment is low and the revenue recovery is fast. The price of hammer crusher is affected by many factors. Different manufacturers of different types of hammer crusher will give different quotes. It is recommended that you come to our company for inspection. Our company is currently a professional manufacturer of hammer crushers in China. Factory price, you can chat online with our service staff at any time to get more detailed information.

| Specification |

Capacity(m³/h) |

Motor Power (kw) |

| PCΦ400×300 |

5-10 |

4P 11KW |

| PCΦ600×400 |

10-22 | 4P 22KW |

| PCΦ800×600 |

18-40 | 6P 55KW |

| PCΦ1000×800 |

25-50 |

8P 75KW |

| PCΦ1000×1000 |

30-55 | 8P 90KW |

| Model | Rotor diameter×length (mm) |

Feed opening Length×width (mm) |

Feeding size (mm) |

Capacity (t/h) |

Power (kw) |

Total weight (t) |

| PCZ1308 | 1300×790 | 910×890 | ≤400 | 100-160 | 132 | 2880×2130×2390 |

| PCZ1410 | 1400×1000 | 1020×750 | ≤500 | 180-230 | 4P 160/2×90 | 2830×2100×2485 |

| PCZ1610 | 1600×1000 | 1150×1000 | ≤600 | 260-350 | 132×2 | 3370×2415×2750 |

| PCZ1615 | 1600×1500 | 1400×1000 | ≤600 | 380-550 | 200×2 | 3370×2925×2750 |

| PCZ1716 | 1700×1600 | 1640×1300 | ≤650 | 600-850 | 250×2 | 3520×3000×3210 |

| PCZ1720 | 1700×2000 | 1980×1300 | ≤650 | 700-1000 | 400×2 | 3670×3390×3330 |

| PCZ1920 | 1900×2000 | 1850×1600 | ≤800 | 900-1500 | 500×2 | 3729×3300×4450 |

| PCZ2225 | 2200×2500 | 2100×2300 | ≤1200 | 1500-3000 | 1250 | 4620×5380×4780 |

| Model |

Rotor×Length(mm) |

Feed Opening Length×Width(mm) |

Max.Feeding Size(mm) |

Capacity(t/h) |

Power(kw) |

Dimensions(L×W×H(mm) |

| PCX-0706 |

700×570 |

618×510 |

≤200 |

50-70 |

75 |

1950×1340×1480 |

| PCX-0808 |

800×750 |

780×610 |

≤200 |

80-100 |

132 |

2280×1790×1570 |

| PCX-0910 |

900×1000 |

1070×750 |

≤200 |

150-200 |

110×2 |

2600×2200×1940 |

| PCX-1012 |

1000×1180 |

1315×900 |

≤200 |

250-300 |

132×2 |

2760×2430×2290 |

| PCX-1213 |

1260×1280 |

1430×1010 |

≤250 |

300-350 |

160×2 |

3067×2622×2580 |

| PCX-1216 |

1260×1490 |

1630×1010 |

≤250 |

400-500 |

200×2 |

3067×2832×2580 |

| PCX-1220 |

1260×1950 |

2090×1010 |

≤250 |

500-700 |

220×2 |

3067×3380×2580 |

| PCX-1622 |

1600×2150 |

2300×980 |

≤300 |

600-900 |

315×2 |

4100×3500×3000 |

| Specification |

Capacity(m³/h) |

Motor Power (kw) |

| PCΦ400×300 |

5-10 |

4P 11KW |

| PCΦ600×400 |

10-22 | 4P 22KW |

| PCΦ800×600 |

18-40 | 6P 55KW |

| PCΦ1000×800 |

25-50 |

8P 75KW |

| PCΦ1000×1000 |

30-55 | 8P 90KW |

| Model | Feeding size (mm) |

Capacity (t/h) |

| PCZ1310 | ≤400 | 100-160 |

| PCZ1410 | ≤500 | 180-230 |

| PCZ1610 | ≤600 | 260-350 |

| PCZ1615 | ≤600 | 380-550 |

| PCZ1716 | ≤650 | 600-850 |

| PCZ1720 | ≤650 | 700-1000 |

| PCZ1900 | ≤800 | 900-1500 |

| PCZ2225 | ≤1200 | 1500-3000 |

| Model |

Max.Feeding Size(mm) |

Capacity(t/h) |

| PCX0706 |

≤200 |

50-75 |

| PCX0808 |

≤200 |

80-100 |

| PCX0910 |

≤200 |

150-200 |

| PCX1012 |

≤250 |

250-300 |

| PCX1213 |

≤250 |

300-350 |

| PCX1216 |

≤250 |

400-500 |

| PCX1220 |

≤250 |

500-700 |

| PCX1622 |

≤300 |

600-900 |

For customization, please contact us.

limestone, granite, cobble, dolomite, bluestone, iron ore, construction waste, glass, etc

Finished product specification: 5-40 (unit: mm) Processing materials:

Henan Hongxing Mining Machinery Co.,Ltd.(HXJQ) covers an area of 350,000 square menters which includes 260,000 square menters of heavey duty industrial workshops.

covers an area of 350,000 square menters .

heavy duty industrial workshops.

which includes 260,000 square menters.

Is a manufacturer of high-end mining machinery in Asia.

All major ports can deliver goods

All major ports can deliver goods

Two weeks of delivery, custom cycle, please consult.

The International standard for some parts, if there are no relevant accessories in the local area, we provide engineer after-sales service.

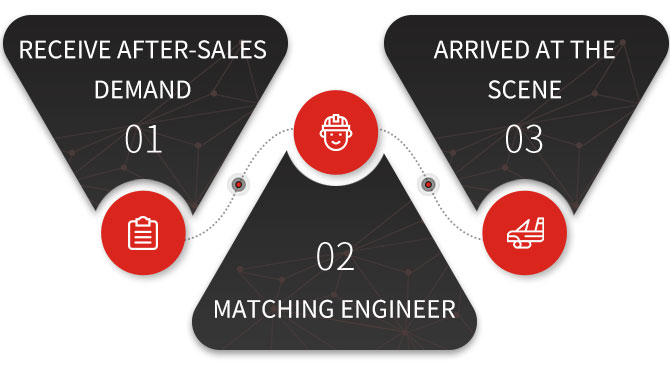

Receive after-sales demand

Matching engineer

02Arrived at the scene