- News & Events

- Blog

- Follow us

“40 years of senior mining machinery solutions”

Made in China

Two weeks delivery, custom cycle, please consult

HLM Series Vertical Mill is a large-scale advanced,high-efficiency and energy-saving grinding product,which integrates grinding, grading,drying and conveying,and has independent intellectual property rights,with the core technology and economic indexes reaching the international advanced level. Widely used in cement building materials coal energy,iron and steel metallurgy,non-metallic minerals,electric power and other industries, suitable for cement raw materials,clinker,desulfurization lime powder,slag,steel slag manganese ore,coal mine and other materials grinding processing.

High efficiency of powder selecting,high quality of products

Adopting dynamic and static combination structure of powder selector,the efficiency of powder selecting is higher. Frequency conversion speed regulation,product fineness adjustment is convenient,so that the finished product size is adjustable between 50-800 mesh,narrow particle size distribution;grinding at the same time the finished product is selected in a timely manner,the finished product is less polluted,high quality.

Simple operation and maintenance

The hydraulic maintenance device can easily turn the grinding rolls out of the machine,and it is convenient to replace the roller sleeve and overhaul the grinding rolls.

High efficiency and energy saving

The grinding rollers and discs are made of special materials,and the roller sleeve can be turned over for long service life. According to many years of production experience,the structure of the roller track is constantly optimized,which improves the output and production efficiency.Equipped with hydraulic loading system,the grinding pressure can be flexibly adjusted according to the change of grindability, high efficiency and energy saving.

High product purity

Limit device to ensure that the grinding disk and rollers are not in direct contact with each other during the working process, the iron content in the product is very low,and the milling consumption per unit of product is generally not higher than 10g/t, and the iron contained in the mechanical abrasion is easy to be removed,which effectively ensures the whiteness and purity of the material.

Wide range of humidity of grindable materials

Vertical mill pulverizing system does not need to be equipped with another dryer,and can directly pass the hot air,in the mill for many times with the full contact with the powder material drying.By adjusting the temperature of the hot air,it can meet the drying requirements of materials with different humidity,and the highest humidity of materials can be up to 15%of the drying.

Clean and environmental protection

Small vibration,low noise,noise is not higher than 80dB. and the use of full negative pressure operation,no dust overflow,reliable sealing,according to different materials to choose a special pulse dust collector,dust removal efficiency of up to 99.9%,higher than the latest national environmental protection standards.

| Specifications | Capacity(t/h) | Pulverized coal fineness | The raw coal moisture | Pulverized coal moisture | Main motor power(kW) |

| HLM1200M | 6—10 | R0.08=5-15% | ≤15% | ≤1-5% | 110-132 |

| HLM1300M | 10-15 | 160—200 | |||

| HLM1500M | 15—20 | 220—280 | |||

| HLM1700M | 20-30 | 280-355 | |||

| HLM1900M | 26-35 | 355—450 | |||

| HLM2200M | 35-50 | 450—560 | |||

| HLM2400M | 45-55 | 560-710 | |||

| HLM2800M | 60-80 | 900—1120 |

Note:Raw coal HGl≥55

| Specifications | Capacity(t/h) | The finished product fineness | The raw material moisture | The finished product moisture | Main motor power(kW) |

| HLM1300K | 10-40 | 0.84-0.37mm (20-400 mesh) | ≤15% | ≤1% | 200 |

| HLM1500K | 13-50 | 280 | |||

| HLM1700K | 18-70 | 400 | |||

| HLM1900K | 20-85 | 500 | |||

| HLM2200K | 35-135 | 800-900 | |||

| HLM2400K | 40-160 | 900-1120 | |||

| HLM2800K | 50-200 | 1120-1250 | |||

| HLM3400K | 70-260 | 1800-2000 | |||

| HLM3700K | 90-320 | 2500-2800 |

Note: The grindability (Bond) index of raw materials is less than or equal to 13kw/t

| Specifications | Capacity(t/h) | Specific surface area | Slag moisture | Mineral moisture | Main motor power(kW) |

| HLM17-2N | 6-10 | ≥420㎡/kg | ≤15% | ≤1% | 200-220 |

| HLM19-2N | 8-13 | 280-315 | |||

| HLM21-2N | 10-15 | 400-450 | |||

| HLM24-2N | 12-18 | 500-560 | |||

| HLM28-2N | 22-30 | 900-1000 | |||

| HLM35-3N | 55-70 | 1800-2000 | |||

| HLM42-4N | 70-100 | 2500-2800 | |||

| HLM46-4N | 85-135 | 3150-3800 | |||

| HLM53-4N | 130-165 | 4500-5000 |

Note: Slag grindability (Bond) index ≤25kw/t; Steel slag grindability (Bond) index ≤30kw/t; The production of steel slag is reduced by about 30-40% when it is ground.

| Specifications | Capacity(t/h) | Product fineness | The raw material moisture | Main motor power(kW) | |

| ≤80μm | ≤2mm | ||||

| HLM17-2Y | 12-20 | ≥30% | ≥90% | ≤3% | 200 |

| HLM19-2Y | 18-25 | 280 | |||

| HLM21-2Y | 25-35 | 400 | |||

| HLM24-2Y | 30-45 | 500 | |||

| HLM28-2Y | 60-80 | 900 | |||

| HLM35-3Y | 125-165 | 1800 | |||

| HLM42-4Y | 200-230 | 2500 | |||

| HLM46-4Y | 250-300 | 3150 | |||

| HLM53-4Y | 360-420 | 4500 | |||

Note: The grindability (Bond) index of raw materials is less than or equal to 18kw/t

| Specifications | Capacity(t/h) | Specific surface area | The raw material moisture | The finished product moisture | Main motor power(kW) |

| HLM19S | 8-13 | ≥380㎡/kg | ≤5% | ≤1% | 280-315 |

| HLM21S | 11-18 | 400-450 | |||

| HLM24S | 15-20 | 500-560 | |||

| HLM28S | 28-35 | 900-1000 | |||

| HLM35S | 70-80 | 1800-2000 | |||

| HLM42S | 95-110 | 2500-2800 | |||

| HLM46S | 130-150 | 3150-3800 | |||

| HLM53S | 160-200 | 4500-5000 |

Note: The grindability (Bond) index of raw materials is less than or equal to 18kw/t

| Specifications | Feed particle size(mm) | Capacity(t/h) | Product fineness | The raw material moisture | Main motor power(kW) |

| HLM1200X | ≤10 | 2-6 | Screen passing rate of 10-40μm 97% | ≤4% | 132 |

| HLM1300X | ≤10 | 3-10 | 220 | ||

| HLM1500X | ≤10 | 4-13 | 315 | ||

| HLM1700X | ≤15 | 7-18 | 450 | ||

| HLM1900X | ≤15 | 8-23 | 560 | ||

| HLM2200X | ≤20 | 13-35 | 800 | ||

| HLM2400X | ≤20 | 15-45 | 1000 |

Note: Mohs hardness grade 4 or below

| Specifications | Capacity(t/h) | Main motor power(kW) |

| HLM1200M | 6—10 | 110-132 |

| HLM1300M | 10-15 | 160—200 |

| HLM1500M | 15—20 | 220—280 |

| HLM1700M | 20-30 | 280-355 |

| HLM1900M | 26-35 | 355—450 |

| HLM2200M | 35-50 | 450—560 |

| HLM2400M | 45-55 | 560-710 |

| HLM2800M | 60-80 | 900—1120 |

Note:Raw coal HGl≥55

| Specifications | Capacity(t/h) | Main motor power(kW) |

| HLM1300K | 10-40 | 200 |

| HLM1500K | 13-50 | 280 |

| HLM1700K | 18-70 | 400 |

| HLM1900K | 20-85 | 500 |

| HLM2200K | 35-135 | 800-900 |

| HLM2400K | 40-160 | 900-1120 |

| HLM2800K | 50-200 | 1120-1250 |

| HLM3400K | 70-260 | 1800-2000 |

| HLM3700K | 90-320 | 2500-2800 |

Note: The grindability (Bond) index of raw materials is less than or equal to 13kw/t

| Specifications | Capacity(t/h) | Main motor power(kW) |

| HLM17-2N | 6-10 | 200-220 |

| HLM19-2N | 8-13 | 280-315 |

| HLM21-2N | 10-15 | 400-450 |

| HLM24-2N | 12-18 | 500-560 |

| HLM28-2N | 22-30 | 900-1000 |

| HLM35-3N | 55-70 | 1800-2000 |

| HLM42-4N | 70-100 | 2500-2800 |

| HLM46-4N | 85-135 | 3150-3800 |

| HLM53-4N | 130-165 | 4500-5000 |

Note: Slag grindability (Bond) index ≤25kw/t; Steel slag grindability (Bond) index ≤30kw/t; The production of steel slag is reduced by about 30-40% when it is ground.

| Specifications | Capacity(t/h) | Main motor power(kW) |

| HLM17-2Y | 12-20 | 200 |

| HLM19-2Y | 18-25 | 280 |

| HLM21-2Y | 25-35 | 400 |

| HLM24-2Y | 30-45 | 500 |

| HLM28-2Y | 60-80 | 900 |

| HLM35-3Y | 125-165 | 1800 |

| HLM42-4Y | 200-230 | 2500 |

| HLM46-4Y | 250-300 | 3150 |

| HLM53-4Y | 360-420 | 4500 |

Note: The grindability (Bond) index of raw materials is less than or equal to 18kw/t

| Specifications | Capacity(t/h) | Main motor power(kW) |

| HLM19S | 8-13 | 280-315 |

| HLM21S | 11-18 | 400-450 |

| HLM24S | 15-20 | 500-560 |

| HLM28S | 28-35 | 900-1000 |

| HLM35S | 70-80 | 1800-2000 |

| HLM42S | 95-110 | 2500-2800 |

| HLM46S | 130-150 | 3150-3800 |

| HLM53S | 160-200 | 4500-5000 |

Note: The grindability (Bond) index of raw materials is less than or equal to 18kw/t

| Specifications | Feed particle size(mm) | Capacity(t/h) | Main motor power(kW) |

| HLM1200X | ≤10 | 2-6 | 132 |

| HLM1300X | ≤10 | 3-10 | 220 |

| HLM1500X | ≤10 | 4-13 | 315 |

| HLM1700X | ≤15 | 7-18 | 450 |

| HLM1900X | ≤15 | 8-23 | 560 |

| HLM2200X | ≤20 | 13-35 | 800 |

| HLM2400X | ≤20 | 15-45 | 1000 |

Note: Mohs hardness grade 4 or below

For customization, please contact us.

Henan Hongxing Mining Machinery Co.,Ltd.(HXJQ) covers an area of 350,000 square menters which includes 260,000 square menters of heavey duty industrial workshops.

covers an area of 350,000 square menters .

heavy duty industrial workshops.

which includes 260,000 square menters.

Is a manufacturer of high-end mining machinery in Asia.

All major ports can deliver goods

All major ports can deliver goods

Two weeks of delivery, custom cycle, please consult.

The International standard for some parts, if there are no relevant accessories in the local area, we provide engineer after-sales service.

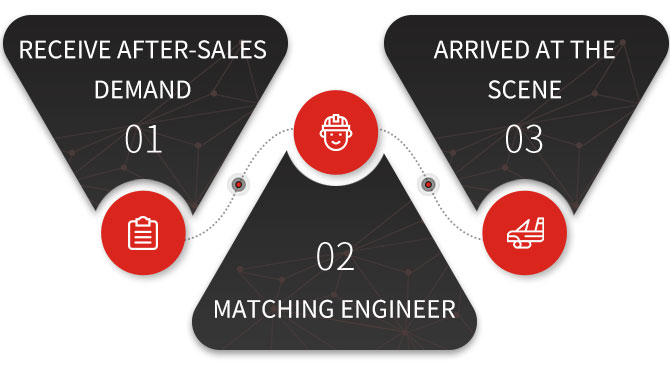

Receive after-sales demand

Matching engineer

02Arrived at the scene