- News & Events

- Blog

- Follow us

Made in China

Two weeks delivery, custom cycle, please consult

HX series circular vibration tilting screen machine is a new type of circular vibrating screen product launched by Hongxing Group for heavy duty condition based on YA and YK series vibrating screen, combined with customers'on-site use and maintenance experi- ence.Mature technology,accessories universal strong.Its vibra- tion strength,high structural strength,and simple maintenance, long service life.Suitable for heavy,medium and fine screening and other screening operations.

The screen-surface inclination angle selection range is 15-23,which can better adapt to the specific working conditions on site;

The exciter is an eccentric shaft eccentric block structure,with a stable transmission and sufficient excitation force;

The vibrator is lubricated with thin oil,and the lubricating oil replaced every six months,making daily maintenance worry-free and labor-saving;

Wear-resistant protective layers are designed in key parts to extend the service life of the equipment;

Pulley transmission can quickly adjust the equipment speed according to on-site working conditions;

Use special bearings for vibration equipment to protect your screening process.

| Model | Sieve Layer | Sieve obliquity (°) |

Vibrating Frequency (r/min) |

Max.Feeding Size (mm) |

Processing Capacity (t/h) |

Power (kw) |

Mesh Size (mm) |

Double Amplitude (mm) |

Dimensions (LxWxH) (mm) |

| 2HX1545 | 2 | 18 | 780-900 | 200 | 45-500 | 15 | 1-130 | 7-12 | 5380×2350×1550 |

| 3HX1545 | 3 | 18 | 780-900 | 200 | 55-500 | 18.5 | 1-130 | 7-12 | 5575×2350×2130 |

| 4HX1545 | 4 | 18-20 | 780-900 | 200 | 65-500 | 22 | 1-130 | 7-12 | 5730×2400×2620 |

| 2HX1855 | 2 | 18 | 780-900 | 200 | 55-600 | 18.5 | 1-130 | 7-12 | 5680×2650×1570 |

| 3HX1855 | 3 | 18 | 780-900 | 200 | 65-600 | 22 | 1-130 | 7-12 | 5900×2655×2250 |

| 4HX1855 | 4 | 18-23 | 780-900 | 200 | 75-600 | 22 | 1-130 | 7-12 | 6030×2660×2640 |

| 2HX2165 | 2 | 18 | 780-900 | 200 | 65-700 | 30 | 1-130 | 7-12 | 7160×2960×1825 |

| 3HX2165 | 3 | 18 | 780-900 | 200 | 75-700 | 30 | 1-130 | 7-12 | 7400×2980×2505 |

| 4HX2165 | 4 | 18-23 | 780-900 | 200 | 85-700 | 37 | 1-130 | 7-12 | 7450×2985×2635 |

| 2HX2465 | 2 | 18 | 780-900 | 200 | 80-800 | 37 | 1-130 | 7-12 | 7160×3270×1825 |

| 3HX2465 | 3 | 18 | 780-900 | 200 | 90-800 | 37 | 1-130 | 7-12 | 7400×3280×2505 |

| 4HX2465 | 4 | 18-23 | 780-900 | 200 | 100-800 | 37 | 1-130 | 7-12 | 7450×3285×2635 |

| 2HX2765 | 2 | 18 | 780-900 | 200 | 100-900 | 37 | 1-130 | 7-12 | 7180×3585×1945 |

| 3HX2765 | 3 | 18 | 780-900 | 200 | 110-900 | 45 | 1-130 | 7-12 | 7390×3600×2585 |

| 4HX2765 | 4 | 18-23 | 780-900 | 200 | 120-900 | 45 | 1-130 | 7-12 | 7480×3600×2855 |

| 2HX3065 | 2 | 18 | 780-900 | 200 | 110-1200 | 37 | 1-130 | 7-12 | 7180×3885×1945 |

| 3HX3065 | 3 | 18 | 780-900 | 200 | 120-1200 | 45 | 1-130 | 7-12 | 7390×3900×2585 |

| 4HX3065 | 4 | 18-23 | 780-900 | 200 | 130-1200 | 45 | 1-130 | 7-12 | 7480×3900×2855 |

| 2HX3074 | 2 | 18 | 780-900 | 200 | 120-1300 | 37 | 1-130 | 7-12 | 3190 3 10×1985 |

| 3HX3074 | 3 | 18 | 780-900 | 200 | 130-1300 | 45 | 1-130 | 7-12 | 8415×3910×2675 |

| 2HX3084 | 2 | 18 | 780-900 | 200 | 130-1300 | 37 | 1-130 | 7-12 | 9200×3900×1985 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Sieve Layer | Sieve obliquity (°) |

Vibrating Frequency (r/min) |

Max.Feeding Size (mm) |

Processing Capacity (t/h) |

Power (kw) |

Mesh Size (mm) |

Double Amplitude (mm) |

Dimensions (LxWxH) (mm) |

| 2HX3075D | 2 | 15-20 | 600-1100 | 300 | 130-1300 | 22×2 | 1-140 | 5-13 | 8695×4080×2145 |

| 3HX3075D | 3 | 15-20 | 600-1100 | 300 | 140-1300 | 37×2 | 1-140 | 5-13 | 8940×4095×2885 |

| 2HX3085D | 2 | 15-20 | 600-1100 | 300 | 150-1300 | 37×2 | 1-140 | 5-13 | 9892×3909×2140 |

| 3HX3085D | 3 | 15-20 | 600-1100 | 300 | 160-1300 | 45×2 | 1-140 | 5-13 | 10132×4100×2880 |

| 2HX3685D | 2 | 15-20 | 600-1100 | 300 | 200-1500 | 37×2 | 1-140 | 5-13 | 9500×5420×2200 |

| 3HX3685D | 3 | 15-20 | 600-1100 | 300 | 220-1500 | 45×2 | 1-140 | 5-13 | 9780×5505×3050 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Sieve Layer | Sieve obliquity (°) |

Processing Capacity (t/h) |

| 2HX1545 | 2 | 18 | 45-500 |

| 3HX1545 | 3 | 18 | 55-500 |

| 4HX1545 | 4 | 18-20 | 65-500 |

| 2HX1855 | 2 | 18 | 55-600 |

| 3HX1855 | 3 | 18 | 65-600 |

| 4HX1855 | 4 | 18-23 | 75-600 |

| 2HX2165 | 2 | 18 | 65-700 |

| 3HX2165 | 3 | 18 | 75-700 |

| 4HX2165 | 4 | 18-23 | 85-700 |

| 2HX2465 | 2 | 18 | 80-800 |

| 3HX2465 | 3 | 18 | 90-800 |

| 4HX2465 | 4 | 18-23 | 100-800 |

| 2HX2765 | 2 | 18 | 100-900 |

| 3HX2765 | 3 | 18 | 110-900 |

| 4HX2765 | 4 | 18-23 | 120-900 |

| 2HX3065 | 2 | 18 | 110-1200 |

| 3HX3065 | 3 | 18 | 120-1200 |

| 4HX3065 | 4 | 18-23 | 130-1200 |

| 2HX3074 | 2 | 18 | 120-1300 |

| 3HX3074 | 3 | 18 | 130-1300 |

| 2HX3084 | 2 | 18 | 130-1300 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Sieve Layer | Sieve obliquity (°) |

Processing Capacity (t/h) |

| 2HX3075D | 2 | 15-20 | 130-1300 |

| 3HX3075D | 3 | 15-20 | 140-1300 |

| 2HX3085D | 2 | 15-20 | 150-1300 |

| 3HX3085D | 3 | 15-20 | 160-1300 |

| 2HX3685D | 2 | 15-20 | 200-1500 |

| 3HX3685D | 3 | 15-20 | 220-1500 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

For customization, please contact us.

Henan Hongxing Mining Machinery Co.,Ltd.(HXJQ) covers an area of 350,000 square menters which includes 260,000 square menters of heavey duty industrial workshops.

covers an area of 350,000 square menters .

heavy duty industrial workshops.

which includes 260,000 square menters.

Is a manufacturer of high-end mining machinery in Asia.

All major ports can deliver goods

All major ports can deliver goods

Two weeks of delivery, custom cycle, please consult.

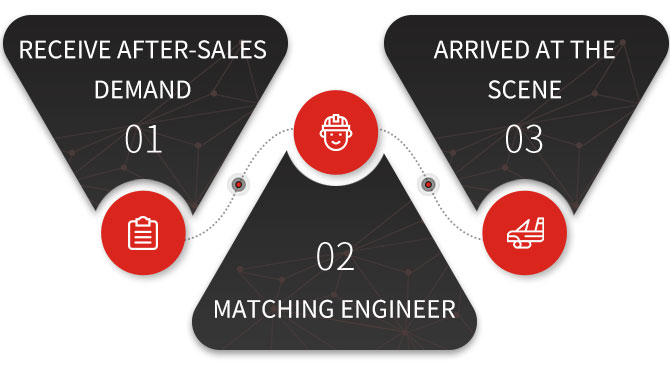

The International standard for some parts, if there are no relevant accessories in the local area, we provide engineer after-sales service.

Receive after-sales demand

Matching engineer

02Arrived at the scene