- News & Events

- Blog

- Follow us

Production capacity: 0.2-21 t/h

“40 years of senior mining machinery solutions”

Made in China

Two weeks delivery, custom cycle, please consult

The micro powder mill is mainly composed of the main machine, a blower, an ultra-fine analyzer, a cyclone powder collector, a bag-type dust collector, and a connecting pipe. According to the needs of users, it can be equipped with some auxiliary equipment, such as the bucket elevator, storage silo, electric control cabinet, powder feeder, crusher, etc.

This micro powder mill is suitable for the super-fine crushing of all kinds of crisp materials whose Mohs hardness is below 9.3, such as calcium carbonate, barite, kaolin, rare earth ore, hematite, talc, feldspar, and furnace slag.

1. The micro powder mill is much cheaper than the airflow mill, which has the same output and fineness as the micro powder mill does.

2. It takes only one-third energy of that of the airflow mill, which has the same output and fineness as the micro powder mill does.

3. Compared with other similar mills, the grinding pressure is increased by 800-1200kg under the action of high-pressure spring

4. It has a big feeding size and the particle size of the final product can reach 6.5um.

The micro powder mill has many price concessions. Manufacturers produce and sell them themselves. 100% ex-factory price guarantee. Save money for customers.

Please tell us your needs, such as materials, capacity or finished product design, we can provide you with better service. Or you can contact the online customer service for free, you can also send an email: info@hxjq.com

| Parameter Model | Micropowder93 | Micropowder92 | Micropowder87 | Micropowder76 | Micropowder66 |

| Feeding size(mm) | ≤25 | ≤25 | ≤20 | ≤20 | ≤15 |

| Size of finished product(mm) | 0.125-0.010 | 0.125-0.033 | 0.125-0.010 | 0.125-0.033 | 0.125-0.010 |

| Shift output of different material fineness(t) | 0.8-12 | 0.6-10 | 0.4-8 | 0.3-6 | 0.2-4 |

| Rotate speed of pulverizing ring(r/min) | 140 | 148 | 160 | 170 | 180 |

| Diameter of pulverizing ring(mm) | 1006 | 973 | 907.5 | 850 | 725 |

| Diameter of pulverizing roller(mm) | 300 | 300 | 270 | 250 | 210 |

| Height of pulverizing roller(mm) | 160 | 160 | 150 | 150 | 150 |

| Main Motor(kw) | Y225M-8-30 | Y225M-8-22 | Y225M-8-22 | Y225S-8-18.5 | Y225M-8-15 |

| Fan Motor | Y180M-2-22 | Y180L-4-22 | Y160L-4-18.5 | Y160L-4-15 | Y160L-4-11 |

| Analyzer Motor | YCT180M-4A-4 | YCT180M-4A-4 | YCT180M-4A-4 | YCT160-4B-3 | YCT160-4B-3 |

| Parameter Model | Feeding size (mm) |

Size of finished product(mm) |

| Micropowder93 | ≤25 | 0.125-0.010 |

| Micropowder92 | ≤25 | 0.125-0.033 |

| Micropowder87 | ≤20 | 0.125-0.010 |

| Micropowder76 | ≤20 | 0.125-0.033 |

| Micropowder66 | ≤15 | 0.125-0.010 |

For customization, please contact us.

coal, feldspar, barite, marble, limestone, talc, calcite, fluorite, kaolin, gypsum, carbon black, clay, etc.

Henan Hongxing Mining Machinery Co.,Ltd.(HXJQ) covers an area of 350,000 square menters which includes 260,000 square menters of heavey duty industrial workshops.

covers an area of 350,000 square menters .

heavy duty industrial workshops.

which includes 260,000 square menters.

Is a manufacturer of high-end mining machinery in Asia.

All major ports can deliver goods

All major ports can deliver goods

Two weeks of delivery, custom cycle, please consult.

The International standard for some parts, if there are no relevant accessories in the local area, we provide engineer after-sales service.

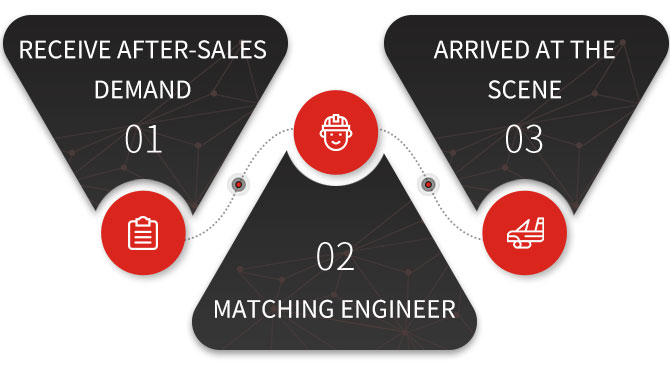

Receive after-sales demand

Matching engineer

02Arrived at the scene