- News & Events

- Blog

- Follow us

Application fields: mining, stone mining, highway (railway) construction, urban construction waste treatment, etc.

“40 years of senior mining machinery solutions”

Made in China

Two weeks delivery, custom cycle, please consult

Wheeled Mobile impact crusher Station is generally equipped with impact crusher. It adopts new manufacturing technology and unique structural design. The finished product is cubic, without tension and crack, and the granular shape is quite good. Mobile impact crusher can crush all kinds, of course, medium and fine materials (granite, limestone, concrete, etc.)

Unit Integration : Superior performance of complete set, reasonable and compact configuration, low requirements for operating sites.

Strong Mobility : Compact structure for the whole set, short turning radius, easy to go in & out and convert the working site.

High Efficiency and Energy Saving : Large feeding port, high crushing chamber, high hardness for material, large block size, little product stone powder.

The Wheeled Mobile impact crusher Station is a series of rock and construction waste crushing equipment, which greatly expands the concept of rough and fine crushing operations. Its design philosophy is to stand on the customer's side and to provide the first solution to eliminate the obstacles of crushing the site, the environment, the complicated basic configuration, and the complicated logistics to the customer's crushing operation.

As a professional provider of construction and mining crushing solutions, we can provide our customers with quality building and mine crushing equipment and provide detailed technical support. Different process requirements are met through an optimized combination of various types of equipment.

| Model | HX938F1210 | HX938F1214 | HX1149F1315 | HX938F1110 | HX1349F1315 |

| Transportation lenght(mm) | 12000 | 12000 | 13900 | 15450 | 15450 |

| Transportation Width(mm) | 2550 | 2550 | 2900 | 2950 | 2950 |

| Transportation Height(mm) | 3900 | 3900 | 4450 | 4500 | 4500 |

| Maximum Lenght(mm) | 12500 | 12500 | 13900 | 15450 | 15450 |

| Maximum Width(mm) | 3250 | 3260 | 3250 | 3250 | 3250 |

| Maximum Height(mm) | 5100 | 5200 | 5200 | 5200 | 5200 |

| Weight(t) | 39 | 44 | 54 | 62 | 62 |

| Impact crusher | PE-1210 | PE-1214 | PF-1315 | HD1110 | HD1315 |

| Maximum Feeding Size(mm) | 350 | 350 | 500 | 400 | 700 |

| Capacity(t/h) | 70-130 | 100-180 | 130-250 | 112 | 280 |

| Vibrating Feeder | ZSW950×3800 | ZSW950×3800 | ZSW110×4900 | ZSW130×4900 | ZSW130×4900 |

| Main Belt Conveyor | B800×8.5M | B800×8.5M | B1000×9.5M | B800×11M | B1200×11M |

| Side-opening Belt conveyor(optional) | B500×3.2m | B500×3.2m | B650×4m | B650×4m | B650×4m |

| Gensrt(optional) | 320KW | 320KW | 400KW | 320KW | 440KW |

| Iron separator(optional) | RCYD(C)-8 | RCYD(C)-8 | RCYD(C)-10 | RCYD(C)-8 | RCYD(C)-12 |

Model HX938F1210 and HX938F1214 and HX1149F1315

| Model | HX938F1210 | HX938F1214 | HX1149F1315 |

| Transportation lenght(mm) | 12000 | 12000 | 13900 |

| Transportation Width(mm) | 2550 | 2550 | 2900 |

| Transportation Height(mm) | 3900 | 3900 | 4450 |

| Maximum Lenght(mm) | 12500 | 12500 | 13900 |

| Maximum Width(mm) | 3250 | 3260 | 3250 |

| Maximum Height(mm) | 5100 | 5200 | 5200 |

| Weight(t) | 39 | 44 | 54 |

| Impact crusher | PE-1210 | PE-1214 | PF-1315 |

| Maximum Feeding Size(mm) | 350 | 350 | 500 |

| Capacity(t/h) | 70-130 | 100-180 | 130-250 |

| Vibrating Feeder | ZSW950×3800 | ZSW950×3800 | ZSW110×4900 |

| Main Belt Conveyor | B800×8.5M | B800×8.5M | B1000×9.5M |

| Side-opening Belt conveyor(optional) | B500×3.2m | B500×3.2m | B650×4m |

| Gensrt(optional) | 320KW | 320KW | 400KW |

| iron separator(optional) | RCYD(C)-8 | RCYD(C)-8 | RCYD(C)-10 |

Model HX938F1110 and HX1349F1315

| Model | HX938F1110 | HX1349F1315 |

| Transportation lenght(mm) | 15450 | 15450 |

| Transportation Width(mm) | 2950 | 2950 |

| Transportation Height(mm) | 4500 | 4500 |

| Maximum Lenght(mm) | 15450 | 15450 |

| Maximum Width(mm) | 3250 | 3250 |

| Maximum Height(mm) | 5200 | 5200 |

| Weight(t) | 62 | 62 |

| Impact crusher | HD1110 | HD1315 |

| Maximum Feeding Size(mm) | 400 | 700 |

| Capacity(t/h) | 112 | 280 |

| Vibrating Feeder | ZSW130×4900 | ZSW130×4900 |

| Main Belt Conveyor | B800×11M | B1200×11M |

| Side-opening Belt conveyor(optional) | B650×4m | B650×4m |

| Gensrt(optional) | 320KW | 440KW |

| Iron separator(optional) | RCYD(C)-8 | RCYD(C)-12 |

For customization, please contact us.

granite, basalt, cobble, bauxite, cement clinker, quartz, silicon carbide, mine, iron ore, etc.

Henan Hongxing Mining Machinery Co.,Ltd.(HXJQ) covers an area of 350,000 square menters which includes 260,000 square menters of heavey duty industrial workshops.

covers an area of 350,000 square menters .

heavy duty industrial workshops.

which includes 260,000 square menters.

Is a manufacturer of high-end mining machinery in Asia.

All major ports can deliver goods

All major ports can deliver goods

Two weeks of delivery, custom cycle, please consult.

The International standard for some parts, if there are no relevant accessories in the local area, we provide engineer after-sales service.

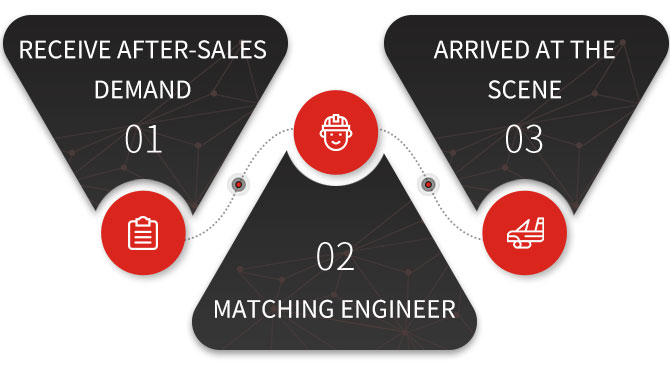

Receive after-sales demand

Matching engineer

02Arrived at the scene