- News & Events

- Blog

- Follow us

Application fields: cement, silicate products, new building materials, refractory materials, glass ceramics and other production industries.

“40 years of senior mining machinery solutions”

Made in China

Two weeks delivery, custom cycle, please consult

The raw material mill is the key equipment for grinding after the crusher process, which is widely used in the manufacture industries, such as cement, new building material, refractory material, nonferrous metal, and glass ceramics, and can be used for dry and wet grinding for all kinds of ores and other grindable materials.

1. Reasonable structure, stable production, large cost saved in equipment operation, smoother operation.

2. The quality of the equipment is certified, no matter what the workmanship is, technology, material, etc., it is more careful, more intelligent, and has a longer service life and lower failure rate.

3. There are many models, and the raw material mill of various models and specifications has different production capacities. There is a wide range of options for users.

4. Comply with the development trend of the times, we design it from the perspectives of environmental protection and low carbon to ensure reasonable control of pollution, smoke, noise, sewage, and others in operation.

As for different types of Raw Material Mills, we use proper driving method and the main driving methods include edge driving and center driving. Inside the cylinder, there are new type classification lining board and standard ladder lining board, which increases the grinding surface of the materials, and the classification effect is better and the follow-up maintenance and spare parts changing are easier. The new partition structure uses an adjustable lifting board and fixed lifting board which is easy to install and maintain.

| (Dia.×Length) (m) |

Speed (r/min) |

Feeding Size (mm) |

Griding Media Loading (t) |

Main Motor (KW) |

Main Reducer |

| Φ2.2×7.0 | 21.7 | <25 | 35 | 380 | ZD70 |

| Φ2.2×7.5 | 21.7 | <25 | 35 | 380 | ZD70 |

| Φ2.2×8.0 | 21.5 | <25 | 36 | 480 | ZD70 |

| Φ2.2×9.0 | 21.5 | <25 | 40 | 480 | ZD70 |

| Φ2.4×7.0 | 21.5 | <25 | 36.5 | 480 | ZD70 |

| Φ2.4×8.0 | 21.5 | <25 | 42 | 570 | ZD80 |

| Φ2.4×9.0 | 21.5 | <25 | 55 | 630 | ZD80 |

| Φ2.4×10 | 20.3 | <25 | 55 | 630 | ZD80 |

| Φ2.6×8.0 | 19.7 | <25 | 51 | 630 | MBY630 |

| Φ2.6×9.0 | 19.7 | <20 | 58 | 710 | MBY630 |

| Φ2.6×10 | 19.7 | <20 | 64 | 800 | MBY710 |

| Φ3.0×9.0 | 18.2 | <20 | 78 | 1000 | MBY800 |

| Φ3.0×11 | 18.2 | <20 | 95 | 1250 | MBY800 |

| Φ3.2×10 | 17.8 | <25 | 100 | 1400 | MBY900 |

| Φ3.2×11 | 17.8 | <25 | 110 | 1400 | MBY900 |

| Φ3.4×7.5 | 16.9 | <20 | 80 | 1000 | MBY800 |

| Φ3.4×7.5+1.8 | 16.9 | <20 | 70 | 1250 | MBY800 |

| Φ3.5×10 | 16.8 | <20 | 140 | 1600 | MBY1000 |

| Φ3.8×7.5 | 16.5 | <15 | 130 | 1600 | MBY1000 |

| Φ3.8×8.5 | 16.5 | <15 | 160 | 1800 | MBY1000 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| (Dia.×Length) (m) |

Speed (r/min) |

Feeding Size (mm) |

Griding Media Loading (t) |

| Φ2.2×7.0 | 21.7 | <25 | 35 |

| Φ2.2×7.5 | 21.7 | <25 | 35 |

| Φ2.2×8.0 | 21.5 | <25 | 36 |

| Φ2.2×9.0 | 21.5 | <25 | 40 |

| Φ2.4×7.0 | 21.5 | <25 | 36.5 |

| Φ2.4×8.0 | 21.5 | <25 | 42 |

| Φ2.4×9.0 | 21.5 | <25 | 55 |

| Φ2.4×10 | 20.3 | <25 | 55 |

| Φ2.6×8.0 | 19.7 | <25 | 51 |

| Φ2.6×9.0 | 19.7 | <20 | 58 |

| Φ2.6×10 | 19.7 | <20 | 64 |

| Φ3.0×9.0 | 18.2 | <20 | 78 |

| Φ3.0×11 | 18.2 | <20 | 95 |

| Φ3.2×10 | 17.8 | <25 | 100 |

| Φ3.2×11 | 17.8 | <25 | 110 |

| Φ3.4×7.5 | 16.9 | <20 | 80 |

| Φ3.4×7.5+1.8 | 16.9 | <20 | 70 |

| Φ3.5×10 | 16.8 | <20 | 140 |

| Φ3.8×7.5 | 16.5 | <15 | 130 |

| Φ3.8×8.5 | 16.5 | <15 | 160 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

For customization, please contact us.

coal, cement, stone, sand, clay, ore, etc

Henan Hongxing Mining Machinery Co.,Ltd.(HXJQ) covers an area of 350,000 square menters which includes 260,000 square menters of heavey duty industrial workshops.

covers an area of 350,000 square menters .

heavy duty industrial workshops.

which includes 260,000 square menters.

Is a manufacturer of high-end mining machinery in Asia.

All major ports can deliver goods

All major ports can deliver goods

Two weeks of delivery, custom cycle, please consult.

The International standard for some parts, if there are no relevant accessories in the local area, we provide engineer after-sales service.

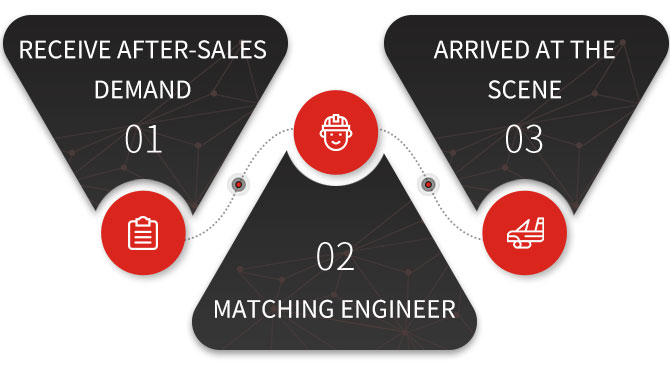

Receive after-sales demand

Matching engineer

02Arrived at the scene