- News & Events

- Blog

- Follow us

Processing capacity:8-800m³/h

Made in China

Two weeks delivery, custom cycle, please consult

The sand screening machine is a kind of common screening machine, widely used in crushing, and sand making, and mineral processing. The vibrating screen is a multi-layer, high-efficiency new vibrating screen, also known as a sorting screen or a screening machine.

limestone, dolomite, cement clinker, iron ore, molybdenum ore, aluminum ore, pebbles, rock.

Sand screening machine with simple structure, convenient maintenance, easy to change the screen surface

Low sieving energy consumption per ton of materials, and environmental protection

Sand screening machine with strong excitation force, no material blockage, high production efficiency

Small vibrating noises, firm and durable construction

With the “people-oriented, customer first, innovation” concept in management and service, except for offering clients our products, we also provide them with reasonable model selection, process allocation, and technical support, to make clients obtain the biggest benefit with a small investment. Thus, we are ready to do clients a favor at any time.

| Model | Sieve Layer | Sieve Area (㎡) |

Mesh Size (mm) |

Max.Feeding Size (mm) |

Processing capacity (m³/h) |

Vibrating Frequency (r/min) |

Double Amplitude (mm) |

Power (kw) |

Sieve Obliquity (°) |

Sieve Specification (mm) |

Dimensions (L×W×H) (mm) |

| 2YK1230 | 2 | 7.2 | 4-50 | 200 | 12-78 | 970 | 6 | 6P 7.5 | 20 | 1200×3000 | 3530×1885×920 |

| 3YK1230 | 3 | 10.8 | 4-50 | 200 | 13-80 | 970 | 6 | 6P 7.5 | 20 | 1200×3000 | 3675×1885×1320 |

| 2YK1237 | 2 | 8.88 | 4-50 | 200 | 15-86 | 970 | 6 | 6P 7.5 | 20 | 1200×3700 | 4230×1990×920 |

| 3YK1237 | 3 | 13.32 | 4-50 | 200 | 16-90 | 970 | 6 | 6P 7.5 | 20 | 1200×3700 | 4375×1990×1320 |

| 2YK1548 | 2 | 14.4 | 5-50 | 200 | 22.5-162 | 970 | 6 | 6P 11 | 20 | 1500×4800 | 5355×2195×1030 |

| 3YK1548 | 3 | 21.6 | 5-50 | 200 | 22.5-162 | 970 | 6 | 6P 15 | 20 | 1500×4800 | 6055×2195×1740 |

| 4YK1548 | 4 | 28.8 | 5-50 | 200 | 22.5-162 | 970 | 6 | 6P 18.5 | 20 | 1500×4800 | 6195×2195×2120 |

| 2YK1854 | 2 | 19.44 | 5-80 | 200 | 32-312 | 970 | 6 | 6P 22 | 20 | 1800×5400 | 6515×2555×1370 |

| 3YK1854 | 3 | 29.16 | 5-80 | 200 | 32-312 | 970 | 6 | 6P 22 | 20 | 1800×5400 | 6655×2555×1750 |

| 4YK1854 | 4 | 38.88 | 5-80 | 200 | 32-336 | 970 | 6 | 6P 22 | 20 | 1800×5400 | 6790×2555×2130 |

| 2YK2160 | 2 | 25.2 | 5-100 | 200 | 50-475 | 970 | 6 | 6P 30 | 20 | 2100×6000 | 7200×2945×1580 |

| 3YK2160 | 3 | 37.8 | 5-100 | 200 | 50-475 | 970 | 6 | 6P 30 | 20 | 2100×6000 | 7340×2945×1980 |

| 4YK2160 | 4 | 50.4 | 5-100 | 200 | 50-497 | 970 | 6 | 6P 37 | 20 | 2100×6000 | 7490×2945×2380 |

| 2YK2460 | 2 | 28.8 | 5-100 | 200 | 65-550 | 970 | 6 | 6P 30 | 20 | 2400×6000 | 7200×3200×1580 |

| 3YK2460 | 3 | 43.2 | 5-100 | 200 | 70-620 | 970 | 6 | 6P 37 | 20 | 2400×6000 | 7340×3200×1980 |

| 4YK2460 | 4 | 57.6 | 5-100 | 200 | 80-680 | 970 | 6 | 6P 45 | 20 | 2400×6000 | 7490×3200×2380 |

| 2YK2866 | 2 | 31 | 5-100 | 200 | 70-650 | 970 | 6 | 6P 37 | 20 | 2800×5600 | 6950×3610×1790 |

| 3YK2866 | 3 | 47 | 5-100 | 200 | 80-700 | 970 | 6 | 6P 45 | 20 | 2800×5600 | 7130×3610×2270 |

| 4YK2866 | 4 | 62 | 5-100 | 200 | 90-750 | 970 | 6 | 6P 55 | 20 | 2800×5600 | 7300×3610×2750 |

| 2YK2873 | 2 | 39.2 | 5-100 | 200 | 70-680 | 970 | 6 | 6P 37 | 20 | 2800×6500 | 7850×3587×1790 |

| 3YK2873 | 3 | 58.8 | 5-100 | 200 | 80-720 | 970 | 6 | 6P 45 | 20 | 2800×6500 | 8025×3587×2270 |

| 4YK2873 | 4 | 58.8 | 5-100 | 200 | 90-950 | 970 | 6 | 6P 55 | 20 | 2800×6500 | 8200×3587×2750 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Sieve Layer | Sieve Area (㎡) |

Processing capacity (m³/h) |

| 2YK1230 | 2 | 7.2 | 12-78 |

| 3YK1230 | 3 | 10.8 | 13-80 |

| 2YK1237 | 2 | 8.88 | 15-86 |

| 3YK1237 | 3 | 13.32 | 16-90 |

| 2YK1548 | 2 | 14.4 | 22.5-162 |

| 3YK1548 | 3 | 21.6 | 22.5-162 |

| 4YK1548 | 4 | 28.8 | 22.5-162 |

| 2YK1854 | 2 | 19.44 | 32-312 |

| 3YK1854 | 3 | 29.16 | 32-312 |

| 4YK1854 | 4 | 38.88 | 32-336 |

| 2YK2160 | 2 | 25.2 | 50-475 |

| 3YK2160 | 3 | 37.8 | 50-475 |

| 4YK2160 | 4 | 50.4 | 50-497 |

| 2YK2460 | 2 | 28.8 | 65-550 |

| 3YK2460 | 3 | 43.2 | 70-620 |

| 4YK2460 | 4 | 57.6 | 80-680 |

| 2YK2866 | 2 | 31 | 70-650 |

| 3YK2866 | 3 | 47 | 80-700 |

| 4YK2866 | 4 | 62 | 90-750 |

| 2YK2873 | 2 | 39.2 | 70-680 |

| 3YK2873 | 3 | 58.8 | 80-720 |

| 4YK2873 | 4 | 58.8 | 90-950 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

For customization, please contact us.

Henan Hongxing Mining Machinery Co.,Ltd.(HXJQ) covers an area of 350,000 square menters which includes 260,000 square menters of heavey duty industrial workshops.

covers an area of 350,000 square menters .

heavy duty industrial workshops.

which includes 260,000 square menters.

Is a manufacturer of high-end mining machinery in Asia.

All major ports can deliver goods

All major ports can deliver goods

Two weeks of delivery, custom cycle, please consult.

The International standard for some parts, if there are no relevant accessories in the local area, we provide engineer after-sales service.

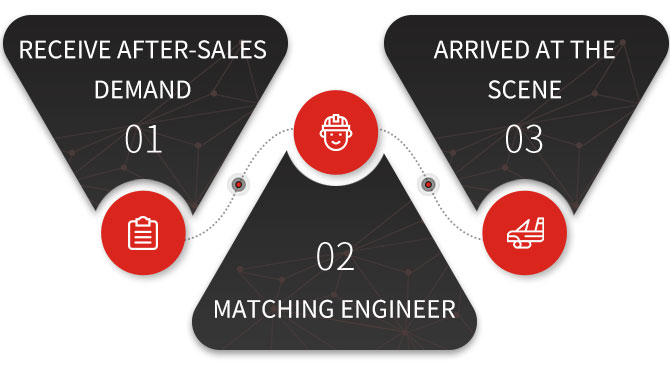

Receive after-sales demand

Matching engineer

02Arrived at the scene