- News & Events

- Blog

- Follow us

Conveying capacity: 30–3000 t/h

“40 years of senior mining machinery solutions”

Made in China

Two weeks delivery, custom cycle, please consult

Belt conveyor is widely used for conveying bulk materials and piece articles in such industrial departments as metallurgy, coal, transportation and water and electricity. According to the specific conveying requirement, one belt conveyor can be used, or several belt conveyors can combine or combine with other conveying machines to form a or slant conveying system.

1. The belt conveyor has advantages of simple structure, convenient maintenance, and low cost.

2. The belt conveyor moves according to the friction drive principle, there is no relative movement between the materials and the belt.

3. The belt conveyor moves according to the friction drive principle and its conveying amount is big, conveying distance is long.

4. Low noise, the conveyance is stable, standard spared parts.

The belt conveyor moves according to the friction drive principle and its conveying amount is big, conveying distance is long and conveyance is stable, and there is no relative movement between the materials and the belt. With the advantages of low noise, simple structure, convenient maintenance, and standard spared parts, it is widely used in the conveyance of bulk materials or piece articles and the production line in mine, metallurgy, chemistry, casting and building material industry and the production departments such as hydropower station construction site and port.

| Belt width(mm) | Conveying length(m) Power(kw) |

Conveying speed(m/s) | Conveying amount(t/h) | ||

| 400 | ≤10 3 |

12-15 3-4 |

15-30 4-7.5 |

1.25-2.0 | 30-60 |

| 500 | ≤10 3 |

12-15 4-5.5 |

15-30 5.5-7.5 |

1.25-2.0 | 40-80 |

| 650 | ≤10 4 |

12-15 7.5 |

15-30 7.5-11 |

1.25-2.0 | 80-120 |

| 800 | ≤10 4 |

12-15 7.5 |

15-30 7.5-15 |

1.25-2.0 | 120-200 |

| 1000 | ≤10 5.5 |

10-20 7.5-11 |

20-40 11-22 |

1.25-2.0 | 200-320 |

| 1200 | ≤10 7.5 |

10-20 7.5-15 |

20-40 15-30 |

1.25-2.0 | 290-480 |

| 1400 | ≤10 11 |

10-20 15-22 |

20-40 22-45 |

1.25-2.0 | 400-680 |

| 1600 | ≤10 15 |

10-20 22-30 |

20-50 30-75 |

1.25-2.0 | 600-1080 |

| 1800 | ≤10 18.5 |

10-20 30-45 |

20-50 45-110 |

1.0-2.0 | 800-1500 |

| 2000 | ≤10 22 |

10-20 45-55 |

20-50 55-132 |

1.0-2.0 | 1000-2000 |

| 2400 | ≤10 30 |

10-20 55-75 |

20-50 75-185 |

1.0-2.0 | 1500-3000 |

| Belt width (mm) |

Conveying speed(m/s) |

Conveying amount(t/h) |

| 400 | 1.25-2.0 | 30-60 |

| 500 | 1.25-2.0 | 40-80 |

| 650 | 1.25-2.0 | 80-120 |

| 800 | 1.25-2.0 | 120-200 |

| 1000 | 1.25-2.0 | 200-320 |

| 1200 | 1.25-2.0 | 290-480 |

| 1400 | 1.25-2.0 | 400-680 |

| 1600 | 1.25-2.0 | 600-1080 |

| 1800 | 1.0-2.0 | 800-1500 |

| 2000 | 1.0-2.0 | 1000-2000 |

| 2400 | 1.0-2.0 | 1500-3000 |

For customization, please contact us.

coal, gravel, sand, cement, chemical fertilizer, food, etc

Henan Hongxing Mining Machinery Co.,Ltd.(HXJQ) covers an area of 350,000 square menters which includes 260,000 square menters of heavey duty industrial workshops.

covers an area of 350,000 square menters .

heavy duty industrial workshops.

which includes 260,000 square menters.

Is a manufacturer of high-end mining machinery in Asia.

All major ports can deliver goods

All major ports can deliver goods

Two weeks of delivery, custom cycle, please consult.

The International standard for some parts, if there are no relevant accessories in the local area, we provide engineer after-sales service.

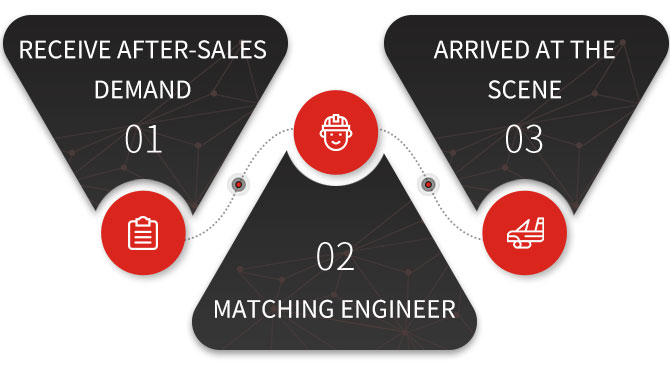

Receive after-sales demand

Matching engineer

02Arrived at the scene