- News & Events

- Blog

- Follow us

Application fields: For the selection of non-ferrous metals, ferrous metals and non-metals.

“40 years of senior mining machinery solutions”

Made in China

Two weeks delivery, custom cycle, please consult

Flotation machine is the abbreviation of the flotation machine, refers to the completion of the flotation process of mechanical equipment. In the flotation machine, the slurry treated with medicament is mixed and aerated, so that some of the ore particles are selectively fixed on the bubbles; Float to the pulp surface to be scraped out to form a foam product, and the rest is retained in the pulp to achieve the purpose of mineral separation.

Flotation machine is mainly used for separation of gold, silver, copper, iron, lead, zinc, molybdenum, nickel, aluminum and other metal minerals. Can also be used for black metal and non - metal selection. Our company produces complete sets of mineral processing equipment and cooperates with a mining research institute to design scientific and reliable mineral processing process flow for you, including gold mineral processing process flow and iron concentrate powder process flow.

| Category | Model | Effective Volume (m³) |

Processing capacity | Main shaft | Loam board | Dimensions (LxWxH) (M) |

||

| Power (kw) |

Rotate speed (r/min) |

Rotate speed (r/min) |

Power (kw) |

|||||

| XJK type flotation machine | XJK-0.35 | 0.35 | 0.18-0.4 | 1.5 | 483 | 25 | 1.1 | 0.7×0.7×0.7 |

| XJK-0.62 | 0.62 | 0.3-0.9 | 3 | 400 | 25 | 1.1 | 0.9×0.82×0.85 | |

| XJK-11 | 1.1 | 0.6-1.6 | 5.5 | 330 | 25 | 1.1 | 1.1×1.1×10 | |

| XJK-2.8 | 2.8 | 1.5-3.5 | 11 | 280 | 25 | 1.1 | 1.75×1.6×1.1 | |

| XJK-5.8 | 5.8 | 5-7 | 22 | 240 | 25 | 1.5 | 2.2×2.2×12 | |

| SF type flotation machine | SF-0.37 | 0.37 | 0.2-0.4 | 1.5 | 386 | 25 | 1.1 | 0.7×0.7×0.75 |

| SF-0.7 | 0.7 | 0.3-0.9 | 3 | 400 | 25 | 1.1 | 0.9×0.82×0.95 | |

| SF-1.2 | 1.2 | 0.6-1.6 | 5.5 | 330 | 25 | 1.1 | 1.1×1.1×1.1 | |

| SF-2.8 | 2.8 | 1.5-3.5 | 11 | 268 | 25 | 1.1 | 1.75×1.6×1.15 | |

| SF-4 | 4 | 2-4 | 15 | 220 | 25 | 1.5 | 1.85×2.05×12 | |

| SF-8 | 8 | 4-8 | 30 | 191 | 25 | 1.5 | 2.2×2.9×1.4 | |

| SF-10 | 10 | 5-10 | 30 | 191 | 25 | 1.5 | 2.2×2.9×1.7 | |

| SF-20 | 20 | 5-20 | 30×2 | 191 | 25 | 1.5 | 2.85×3.8×2.0 | |

| JJF type flotation machine | JJF-2 | 2 | 1-3 | 7.5 | 443 | 25 | 1.5 | 1.4×1.4×1.1 |

| JJF-4 | 4 | 2-4 | 11 | 305 | 25 | 1.5 | 1.6×2.15×1.25 | |

| JJF-8 | 8 | 4-8 | 22 | 233 | 25 | 1.5 | 2.2×2.9×1.4 | |

| JJF-10 | 10 | 5-10 | 22 | 233 | 25 | 1.5 | 2.2×2.9×1.7 | |

| JJF-16 | 16 | 5-16 | 30 | 180 | 25 | 1.5 | 2.85×3.8×1.7 | |

| JJF-20 | 20 | 5-20 | 37 | 180 | 25 | 1.5 | 2.9×3.8×20 | |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Trough cubage (m³) |

Inside dimensions (L×W×H) (m) |

Air suction amount (m³/㎡·min) |

Power (kw) |

Motor model | Processing capacity (m³/min) |

Single trough weight (t) |

| BF-0.37 | 0.37 | 0.74×0.74×0.75 | 0.9~1.05 | 1.5 | Y90L-4 | 0.2~0.4 | 0.5 |

| BF-0.65 | 0.65 | 0.85×0.95×0.9 | 0.9~1.10 | 3.0 | Y132S-6 | 0.3~0.7 | 1.0 |

| BF-1.2 | 1.2 | 1.05×1.15×1.10 | 1.0~1.10 | 5.5 4.0 |

Y132M2-6 Y132M1-6 |

0.6~1.2 | 1.4 |

| BF-2.0 | 2.0 | 1.40×1.45×1.12 | 1.0~1.10 | 7.5 | Y160M-6 | 1.0~2.0 | 1.8 |

| BF-2.8 | 2.8 | 1.65×1.65×1.15 | 0.9~1.10 | 11 | Y180L-8 | 1.4~3.0 | 2.2 |

| BF-4.0 | 4.0 | 1.9×2.0×1.2 | 0.9~1.10 | 15 | Y200L-8 | 2~4 | 2.6 |

| BF-6.0 | 6.0 | 2.2×2.35×1.3 | 0.9~1.10 | 18.5 | Y225S-8 | 3~6 | 3.3 |

| BF-8.0 | 8.0 | 2.25×2.85×1.4 | 0.9~1.10 | 22 30 |

Y225M-8 Y250M-8 |

4~8 | 4.2 |

| BF-10 | 10 | 2.25×2.85×1.7 | 0.9~1.10 | 22 30 |

Y225M-8 Y250M-8 |

5~10 | 4.7 |

| BF-16 | 16 | 2.85×3.8×1.7 | 0.9~1.10 | 37 45 |

Y280S-8 Y280M-8 |

8~16 | 8.4 |

| BF-20 | 20 | 2.85×3.8×2.0 | 0.9~1.10 | 37 45 |

Y280S-8 Y280M-8 |

10~20 | 8.7 |

| BF-24 | 24 | 3.15×4.15×2.0 | 0.9~1.10 | 45 | Y280M-8 | 12~24 | 9.2 |

| Model | Effective Volume (m³) |

Processing capacity |

| XJK-0.35 | 0.35 | 0.18-0.4 |

| XJK-0.62 | 0.62 | 0.3-0.9 |

| XJK-11 | 1.1 | 0.6-1.6 |

| XJK-2.8 | 2.8 | 1.5-3.5 |

| XJK-5.8 | 5.8 | 5-7 |

| SF-0.37 | 0.37 | 0.2-0.4 |

| SF-0.7 | 0.7 | 0.3-0.9 |

| SF-1.2 | 1.2 | 0.6-1.6 |

| SF-2.8 | 2.8 | 1.5-3.5 |

| SF-4 | 4 | 2-4 |

| SF-8 | 8 | 4-8 |

| SF-10 | 10 | 5-10 |

| SF-20 | 20 | 5-20 |

| JJF-2 | 2 | 1-3 |

| JJF-4 | 4 | 2-4 |

| JJF-8 | 8 | 4-8 |

| JJF-10 | 10 | 5-10 |

| JJF-16 | 16 | 5-16 |

| JJF-20 | 20 | 5-20 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Trough cubage (m³) |

Processing capacity (m³/min) |

| BF-0.37 | 0.37 | 0.2~0.4 |

| BF-0.65 | 0.65 | 0.3~0.7 |

| BF-1.2 | 1.2 | 0.6~1.2 |

| BF-2.0 | 2.0 | 1.0~2.0 |

| BF-2.8 | 2.8 | 1.4~3.0 |

| BF-4.0 | 4.0 | 2~4 |

| BF-6.0 | 6.0 | 3~6 |

| BF-8.0 | 8.0 | 4~8 |

| BF-10 | 10 | 5~10 |

| BF-16 | 16 | 8~16 |

| BF-20 | 20 | 10~20 |

| BF-24 | 24 | 12~24 |

For customization, please contact us.

gold ore, copper ore, molybdenum ore, aluminum ore, lead ore, talc, coal fluorite, bauxite, potassium feldspar, quartz stone, etc.

Henan Hongxing Mining Machinery Co.,Ltd.(HXJQ) covers an area of 350,000 square menters which includes 260,000 square menters of heavey duty industrial workshops.

covers an area of 350,000 square menters .

heavy duty industrial workshops.

which includes 260,000 square menters.

Is a manufacturer of high-end mining machinery in Asia.

All major ports can deliver goods

All major ports can deliver goods

Two weeks of delivery, custom cycle, please consult.

The International standard for some parts, if there are no relevant accessories in the local area, we provide engineer after-sales service.

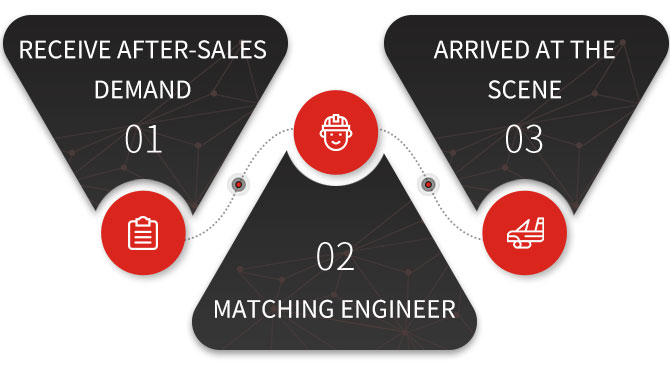

Receive after-sales demand

Matching engineer

02Arrived at the scene