- News & Events

- Blog

- Follow us

Application fields: ore crushing, railways, highways, energy, cement, chemicals, construction and other industries.

“40 years of senior mining machinery solutions”

Made in China

Two weeks delivery, custom cycle, please consult

The new impact crusher integrates the current domestic and international new technology to refine the rotor and crushing cavity for different fields of application. We use new high wear-resistant materials to greatly improve equipment performance and throughput. It is a kind of very important mining crushing equipment. The size of the discharge size can be adjusted, and the crushing specifications are diversified.

1. It has a big feeding mouth, high crushing chamber, high adaptability of the material hardness and a small number of stone powders.

2. The gap between the impacting plate and the plate hammer is convenient to adjust so that it can effectively control the discharging granularity and the particle shape is good.

3. It has a compact structure and strong rigidness, and the rotor has big rotational inertia.

4. It adopts high chromium plate so that it has shock resistance, abrasion resistance, and big impacting force.

5. It adopts no key links so that it is convenient for maintenance and repair and economical and reliable.

After nearly 40 years of industry experience, Hongxing mining machinery has absorbed the latest technology and concepts at home and abroad to develop products with an international advanced level. The Hongxing machine has formed its own unique and rich corporate culture.

Impact crusher is one of our hot products, which is exported to more than 100 countries and regions around the world. However, we meet the customer's needs for the ultimate goal and promise 100% ex-factory price to save costs for customers. We have more products and industry information waiting for you to know! Welcome to consult online at any time. You can also send an email to info@hxjq.com to consult us.

| Model | Specification (mm) |

Feed opening (mm) |

The Maximum Feeding Size (mm) |

Capacity (t/h) |

Power (kw) |

Overall dimension (L×W×H) (mm) |

Total weight (t) |

| PF-1007 | Φ1000×700 | 400×730 | 300 | 30-70 | 4P 37-45 | 2330×1660×2300 | 12 |

| PF-1010 | Φ1000×1050 | 400×1080 | 350 | 50-90 | 4P 45-55 | 2370×1700×2390 | 15 |

| PF-1210 | Φ1250×1050 | 400×1080 | 350 | 70-130 | 6P 110 | 2680×2160×2800 | 17.7 |

| PF-1214 | Φ1250×1400 | 400×1430 | 350 | 80-180 | 6P 132 | 2650×2460×2800 | 22.4 |

| PF-1315 | Φ1320×1500 | 860×1520 | 500 | 100-280 | 6P 200 | 3180×2720×3120 | 27 |

| PF-1320 | Φ1300×2000 | 993×2000 | 500 | 140-380 | 6P 250 | 3220×3100×3120 | 34 |

| PF-1520 | Φ1500×2000 | 830×2040 | 700 | 200-550 | 4P 315-400 | 3959×3564×3330 | 50.6 |

| PF-1820 | Φ1800×2000 | 1260×2040 | 800 | 400-800 | 4P 630-710 | 4400×3866×4009 | 83.21 |

| Model | Rotor(mm) | The Maximum Feeding Size(mm) | Capacity(t/h) | Motor power(kw) | Overall dimension(L×W×H)(mm) | Weight(kg) | |

| -150MPa | -350MPa | ||||||

| HD1110 | Φ1040×1000 | 400 | 200 | 90~190 | 4P 90-132 | 3000×2360×2385 | 15875 |

| HD1315 | Φ1300×1500 | 700 | 300 | 180~280 | 4P 200-270 | 3735×3156×3055 | 29600 |

| HD1520 | Φ1500×2000 | 1000 | 400 | 350~500 | 4P 400-500 | 4310×3330×3660 | 42000 |

| HD1625 | Φ1650×2500 | 1300 | 500 | 500~670 | 4P 500-670 | 5540×4330×4600 | 66000 |

| Model | Maximum Feeding Size (mm) | Power (kw) | Capacity (t/h) | Dimensions(L×W×H)(mm) |

| CI1110 | 250 | 160 | 60-210 | 2826×2087×2285 |

| CI1213 | 300 | 200 | 80-280 | 2903×2530×2411 |

| CI1316 | 300 | 250 | 100-350 | 3320×2770×2535 |

| C11321 | 300 | 315 | 130-430 | 2955×3285×2585 |

| C11521 | 350 | 2×(200-250) | 200-600 | 3450×3620×2770 |

| Cl1524 | 350 | 2×315 | 240-700 | 3450×3925×2855 |

| Cl1630 | 400 | 710-800 | 300-900 | 3693×4520×3173 |

| Model | Maximum Feeding Size (mm) | Power (kw) | Capacity (t/h) | Dimensions(L×W×H)(mm) |

| CI1313 | 600 | 200 | 100-480 | 2972×2560×2937 |

| CI1415 | 600 | 250 | 120-600 | 2985×2790×3068 |

| CI1620 | 800 | 2×(200-250) | 220-900 | 4261×3480×3780 |

| CI2023 | 800 | 2×500 | 400-2000 | 5151×4424×4712 |

| Model | Feed opening (mm) |

The Maximum Feeding Size (mm) |

Capacity (t/h) |

| Φ1000×700 | 400×730 | 300 | 30-70 |

| Φ1000×1050 | 400×1080 | 350 | 50-90 |

| Φ1250×1050 | 400×1080 | 350 | 70-130 |

| Φ1250×1400 | 400×1430 | 350 | 80-180 |

| Φ1320×1500 | 860×1520 | 500 | 100-280 |

| Φ1300×2000 | 993×20000 | 500 | 140-380 |

| Φ1500×2000 | 830×2040 | 700 | 200-550 |

| Φ1800×2000 | 1260×2040 | 800 | 400-800 |

| Rotor (mm) |

Discharging (mm) |

Capacity (t/h) |

|

| -150MPa | -350MPa | ||

| Φ1040×1000 | 400 | 200 | 90-190 |

| Φ1300×1500 | 700 | 300 | 180~280 |

| Φ1500×2000 | 1000 | 400 | 350~500 |

| Φ1650×2500 | 1300 | 500 | 500~670 |

| Model | Maximum Feeding Size (mm) | Capacity(t/h) |

| CI1110 | 250 | 60-210 |

| CI1213 | 300 | 80-280 |

| CI1316 | 300 | 100-350 |

| C11321 | 300 | 130-430 |

| C11521 | 350 | 200-600 |

| Cl1524 | 350 | 240-700 |

| Cl1630 | 400 | 300-900 |

| Model | Maximum Feeding Size (mm) | Capacity(t/h) |

| CI1313 | 600 | 100-480 |

| CI1415 | 600 | 120-600 |

| CI1620 | 800 | 220-900 |

| CI2023 | 800 | 200-2000 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

For customization, please contact us.

limestone, granite, river pebbles, basalt, concrete, aggregate, dolomite, iron ore, gold ore, coal , slag.etc

Finished product specification: 10-80 (unit: mm) Processing materials:

Henan Hongxing Mining Machinery Co.,Ltd.(HXJQ) covers an area of 350,000 square menters which includes 260,000 square menters of heavey duty industrial workshops.

covers an area of 350,000 square menters .

heavy duty industrial workshops.

which includes 260,000 square menters.

Is a manufacturer of high-end mining machinery in Asia.

All major ports can deliver goods

All major ports can deliver goods

Two weeks of delivery, custom cycle, please consult.

The International standard for some parts, if there are no relevant accessories in the local area, we provide engineer after-sales service.

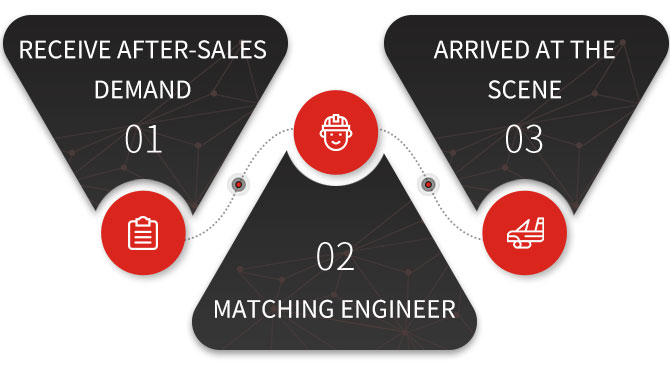

Receive after-sales demand

Matching engineer

02Arrived at the scene