- News & Events

- Blog

- Follow us

Applicable materials: gold ore, iron ore, river sand, quartz sand, copper ore , etc

“40 years of senior mining machinery solutions”

Made in China

Two weeks delivery, custom cycle, please consult

Indirect Heat Transfer Dryer are mainly used in sand and gravel yard, mining, coal mining, concrete mixing plant, dry mortar, power plant desulfurization, refractory materials, building materials, and many other industries. There are mainly rotary dryers and indirect heat transfer dryers.

Indirect Heat Transfer Dryer are used to dry more than 200 kinds of materials such as lime, limestone, river sand, clay, river sand, quartz sand, gold ore, iron ore, copper ore.

Fast heat transfer and wide drying surface

Reasonable parameter design and low energy consumption

Energy saving and high efficiency, high application value

Simple operation, and environmental protection

The parts have a long life and are not easy to wear

Indirect Heat Transfer Dryer have low investment and high returns, which is an option that investors cannot miss. Our goal is to work with you to maximize the profitability of your business. Tailored solutions that help you meet your business targets.

We have professional engineers who can customize the most economical and reasonable engineering solutions according to the project information you provide. You can leave your contact information and product requirements in the message form below, such as the materials you need to dry, the capacity, etc. Or you can send an email to info@hxjq.com. We will contact you as soon as possible.

| Shell diameter × shell Length | Inside diameter of outer shell (mm) |

Inside diameter of inner shell (mm) |

Shell Length (m) |

Shell cubage (m³) |

Shell obliquity | Lifting blade form | Highest inlet air temperature (℃) |

Dimensions (m) |

| Φ1.5×15m | 1500 | 500 | 15 | 20.27 | 3-5% | Lifting form | 850 | 16.2×2.7×2.7 |

| Φ1.5×17m | 17 | 22.97 | 18.2×2.7×2.7 | |||||

| Φ1.5×19m | 19 | 25.68 | 20.0×2.9×2.9 | |||||

| Φ1.8×21m | 1800 | 650 | 21 | 35.91 | 3-5% | Lifting form | 850 | 22.5×2.7×2.7 |

| Φ1.8×23m | 23 | 39.33 | 24.5×2.9×2.9 | |||||

| Φ1.8×25m | 25 | 42.75 | 26.5×2.9×2.9 | |||||

| Φ2.2×21m | 2200 | 800 | 21 | 58.10 | 3-5% | Lifting form | 850 | ---- |

| Φ2.2×23m | 23 | 63.61 | ||||||

| Φ2.2×25m | 25 | 69.15 |

| Shell diameter × shell Length | Inside diameter of outer shell (mm) |

Inside diameter of inner shell (mm) |

Shell cubage (m³) |

| Φ1.5×15m | 1500 | 500 | 20.27 |

| Φ1.5×17m | 22.97 | ||

| Φ1.5×19m | 25.68 | ||

| Φ1.8×21m | 1800 | 650 | 35.91 |

| Φ1.8×23m | 39.33 | ||

| Φ1.8×25m | 42.75 | ||

| Φ2.2×21m | 2200 | 800 | 58.10 |

| Φ2.2×23m | 63.61 | ||

| Φ2.2×25m | 69.15 |

For customization, please contact us.

metallurgy, building materials, food, light industry, chemical industry

Henan Hongxing Mining Machinery Co.,Ltd.(HXJQ) covers an area of 350,000 square menters which includes 260,000 square menters of heavey duty industrial workshops.

covers an area of 350,000 square menters .

heavy duty industrial workshops.

which includes 260,000 square menters.

Is a manufacturer of high-end mining machinery in Asia.

All major ports can deliver goods

All major ports can deliver goods

Two weeks of delivery, custom cycle, please consult.

The International standard for some parts, if there are no relevant accessories in the local area, we provide engineer after-sales service.

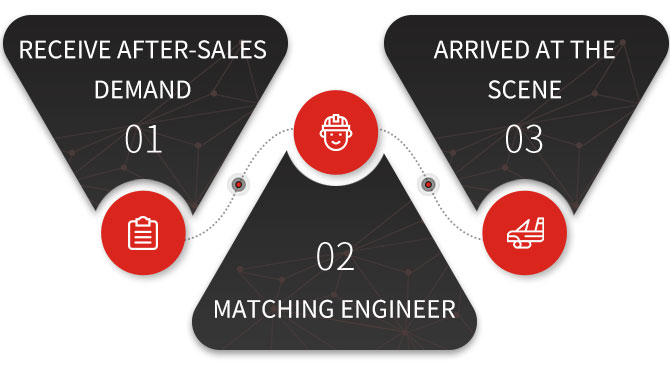

Receive after-sales demand

Matching engineer

02Arrived at the scene