- News & Events

- Blog

- Follow us

Application fields: metallurgy, chemical, building materials, electricity, transportation and other departments.

“40 years of senior mining machinery solutions”

Made in China

Two weeks delivery, custom cycle, please consult

The mining crusher is an indispensable process for the crushing production line. it can be used to crush once, twice and finely crushed more than 200 kinds of rough stones such as granite, basalt, limestone, rock, concrete, aggregate, gravel, dolomite and quartz. It is widely used in mining, quarry, construction, road, and other industries.

The machine is sold to more than 120 countries and regions around the world. Such as Zimbabwe, Ethiopia, Zambia, Guinea, Kenya, Algeria, Egypt, Saudi Arabia, Kazakhstan, Turkey, Oman, Azerbaijan, India, Nepal, the Philippines, Pakistan, Malaysia, Canada, Austria, Italy, Papua New Guinea, New Zealand, Mexico, Brazil, and other countries

1. Large crushing ratio, uniform product size, and high production efficiency.

2. Advanced structure, reliable operation, and low operating costs.

3. Convenient operation and maintenance, environmental protection and energy saving.

4. Advanced manufacturing, pressure and wear resistance.

Service Concept: Creating value for clients; satisfying clients’ needs.

Service Target: Beyond clients’ expectation; beyond industry standards.

Service Strategy: To lower the clients’ cost by the standard, diverse, and beneficial service, to increase Hongxing’s competitiveness in brand and service.

Service Guarantee: 24h online technical people for you; if the fault hasn’t been disposed of completely, our service engineer can’t leave the actual site until we get the client’s permission.

Hongxing adheres to the service concept of creating value for clients and satisfying clients’ needs, with high speed, advanced techniques, and sincere attitude.

| Model | Feed opening size(mm) | Max.Feeding size (mm) | Adjustment range of discharge port (mm) | Capacity(t/h) | Rotation speed of eccentric shaft(r/min) | Power (kw) | Dimensions(L×W×H) (mm) |

| PE 150×250 | 150×250 | 125 | 10-40 | 1-3 | 268 | 4P 5.5 | 760×700×860 |

| PE 200×300 | 200×300 | 180 | 15-50 | 2-6 | 260 | 4P 7.5 | 915×780×990 |

| PE 200×350 | 200×350 | 180 | 18-60 | 3-10 | 276 | 4P 11 | 1000×914×1112 |

| PE 250×400 | 250×400 | 210 | 20-70 | 5-21 | 300 | 6P 15 | 1100×1032×1285 |

| PE 400×600 | 400×600 | 340 | 40-100 | 16-64 | 270 | 6P 30 | 1623×1736×1615 |

| PE 500×750 | 500×750 | 425 | 50-100 | 40-110 | 268 | 6P 55 | 1920×1850×1920 |

| PE 600×750 | 600×750 | 500 | 150-200 | 80-240 | 268 | 6P 55 | 2020×1850×1920 |

| PE 600×900 | 600×900 | 500 | 65-160 | 50-160 | 254 | 6P 55 | 2530×1900×2340 |

| PE 750×1060 | 750×1060 | 630 | 80-180 | 110-320 | 245 | 8P 110 | 2680×2380×2785 |

| PE 900×1200 | 900×1200 | 750 | 100-200 | 220-380 | 208 | 8P 110 | 3470×2876×3330 |

| PE1200×1500 | 1200×1500 | 1020 | 150-350 | 400-1000 | 180 | 8P 160-245 | 4850×3220×3680 |

| PE1500×1800 | 1500×1800 | 1200 | 220-350 | 500-1200 | 180 | 8P 280-380 | 5160×3660×4248 |

| PEX 150×750 | 150×750 | 120 | 18-48 | 8-25 | 320 | 4P 15 | 1170×1575×1030 |

| PEX 250×750 | 250×750 | 210 | 25-60 | 13-35 | 320 | 6P 22 | 1550×1730×1470 |

| PEX 250×1000 | 250×1000 | 210 | 25-60 | 16-52 | 330 | 6P 30 | 1580×2006×1390 |

| PEX 250×1200 | 250×1200 | 210 | 25-60 | 20-61 | 330 | 6P 37 | 1780×2214×1430 |

| PEX 300×1300 | 300×1300 | 250 | 20-90 | 16-105 | 300 | 6P 55 | 2210×2320×1723 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Max.Feeding size (mm) | Capacity (t/h) |

| PE 150×250 | 125 | 1-3 |

| PE 200×300 | 180 | 2-6 |

| PE 200×350 | 180 | 3-10 |

| PE 250×400 | 210 | 5-21 |

| PE 400×600 | 340 | 16-64 |

| PE 500×750 | 425 | 40-110 |

| PE 600×750 | 500 | 80-240 |

| PE 600×900 | 500 | 50-160 |

| PE 750×1060 | 630 | 110-320 |

| PE 900×1200 | 750 | 220-380 |

| PE 1200×1500 | 1020 | 400-1000 |

| PE 1500×1800 | 1200 | 500-1200 |

| PEX 150×750 | 120 | 8-25 |

| PEX 250×750 | 210 | 13-35 |

| PEX 250×1000 | 210 | 16-52 |

| PEX 250×1200 | 210 | 20-61 |

| PEX 300×1300 | 250 | 16-105 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

For customization, please contact us.

barite, calcite, coal, concrete, aggregate, gravel, basalt, cement, gypsum, limestone, granite, rock and so on.

Henan Hongxing Mining Machinery Co.,Ltd.(HXJQ) covers an area of 350,000 square menters which includes 260,000 square menters of heavey duty industrial workshops.

covers an area of 350,000 square menters .

heavy duty industrial workshops.

which includes 260,000 square menters.

Is a manufacturer of high-end mining machinery in Asia.

All major ports can deliver goods

All major ports can deliver goods

Two weeks of delivery, custom cycle, please consult.

The International standard for some parts, if there are no relevant accessories in the local area, we provide engineer after-sales service.

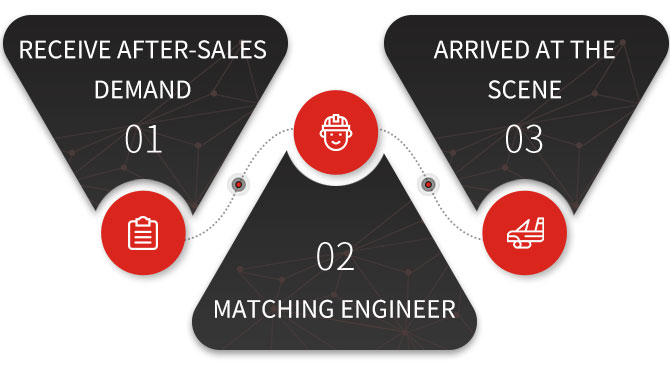

Receive after-sales demand

Matching engineer

02Arrived at the scene